Challenge addressed

Project

Future sustainable and low-carbon energy and chemistry largely depend on the development of new innovative solutions to enable an effective and direct use of renewable energy for the one-step conversion of small molecules such as CH4, CO2 and N2, the core target of the SCOPE project. The PIs of this SCOPE project are among the pioneering groups (highly cited) showing how the direct conversion of these small molecules driven by renewable energy is a key enabling factor to move to a renewable energy-driven chemistry and energy, with a drastic decrease in carbon footprint, up to over 90%. This breakthrough decrease (for example, in N2 fixation to NH3) is possible due to the combination of various factors: i) the use of renewable energy as energy source, ii) avoiding the use of fossil fuels (such as H2 and energy source), and not least iii) the significant reduction in process steps and iv) the use of mild reaction conditions. N2 fixation under mild conditions (near room temperature and ambient pressure) is one of the current grand challenges for catalysis and a sustainable low-carbon future. Realizing a distributed production (i.e. at regional level) allows further benefits in terms of flexibility, integration in the electrical grid, avoid large productions in a single place, with issues related to environmental impact and chemicals transport at long distance. For this reason, the interest for a distributed fertilizers production, for example, is increasing.

These technologies allow also another relevant target: produce remotely (where renewable energy is available) energy vectors, and use this chemical energy storage to store and transport renewable energy on a long-distance scale. Chemical energy storage (through CO2 conversion) is an enabling element to switch from a centralized energy production model to a new energy model based on distributed energy production/storage. It is thus a crucial technology to shift from a fossil fuel- to a renewable energy-based energy system.

CH4 direct valorization to longer C-chain hydrocarbons (olefins, in particular) is another key technology to valorize stranded natural gas or shale gas resources, or valorize biogas (a mixture of CH4 and CO2) resources, in combination with CO2 use as a novel carbon source. N2 direct valorization to NH3 can yield high energy-density engine fuels, and valorization to NOx can yield flexible, on-site fertilizer supply for precision agriculture such as vertical farming and hydro-ponics.

Direct and low carbon footprint processes, suitable for distributed use and using directly renewable energy as energy source, are thus an enabling element to move to a future sustainable (low carbon) energy and chemical production. The direct conversion of CH4, CO2 and N2, realized in mild reaction conditions through the use of renewable energy, addresses thus a crucial aspect for transition to a sustainable chemistry and energy and creates the fundamental bases for breakthrough novel (industrial) processes.

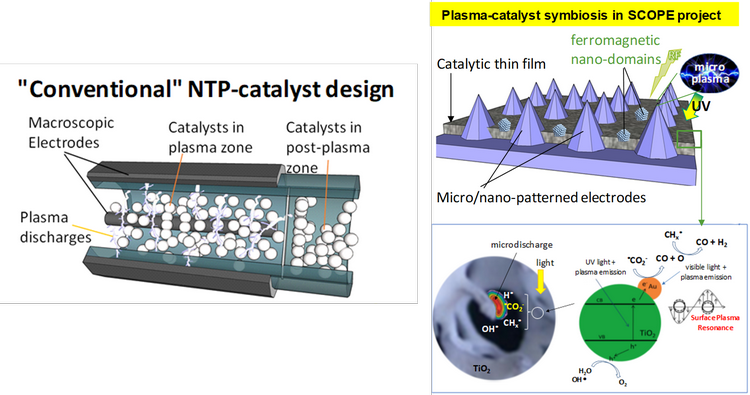

We propose a highly innovative approach for plasma-catalysis symbiosis, based on three game-changing enablers, which have NOT been explored earlier:

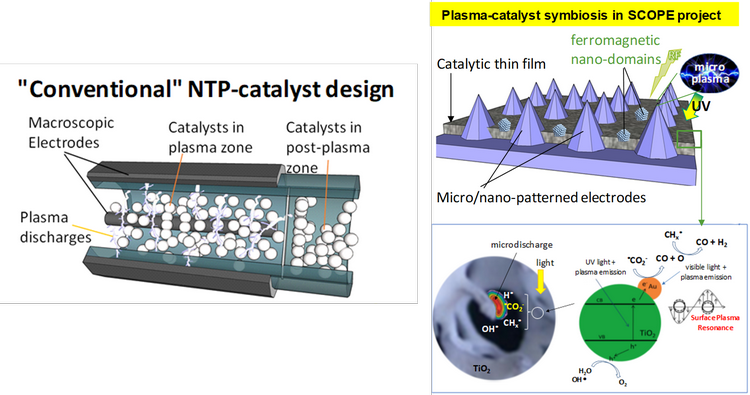

- By inducing excited states in solid catalysts to work in synergy with the excited short-lived species created by plasma interaction with the target feeds, we introduce a brand new idea for catalyst-plasma symbiosis, because we create conditions for synergetic interaction between them, along two possibilities: i) generate localized surface electrons, which may positively interact with the radicals generated in plas-ma, and drive their transformation along selective pathways; semiconductor or electrocatalysts will be used for this purpose. ii) couple surface plasmons (i.e. surface vibrationally excited states) and photo-electronic or vibrationally-excited gas-species generated in plasma. Plasmonic-type catalysts will be used.

- With a fully new concept of nano-/micro-plasma array through a novel electrode design, we generate plasma locally at the catalyst surface, overcoming long distance transport. We thus introduce the new con-cept of confined dimension of plasma (micronisation). 3D printing and other methods will be used to pre-pare these nanopatterned electrodes with catalytic thin films.

- By embedding ferromagnetic nano-domains in the catalyst support and inducing radiofrequency heat-ing, fast temperature modulations directly at the catalyst active sites are generated, introducing a further el-ement to improve the catalytic reactivity over stationary conditions.

These three enablers, initially studied separately, will be integrated and optimized in relation to the three target reactions.